The impact of Core Drilling Equipment on modern infrastructure

Wiki Article

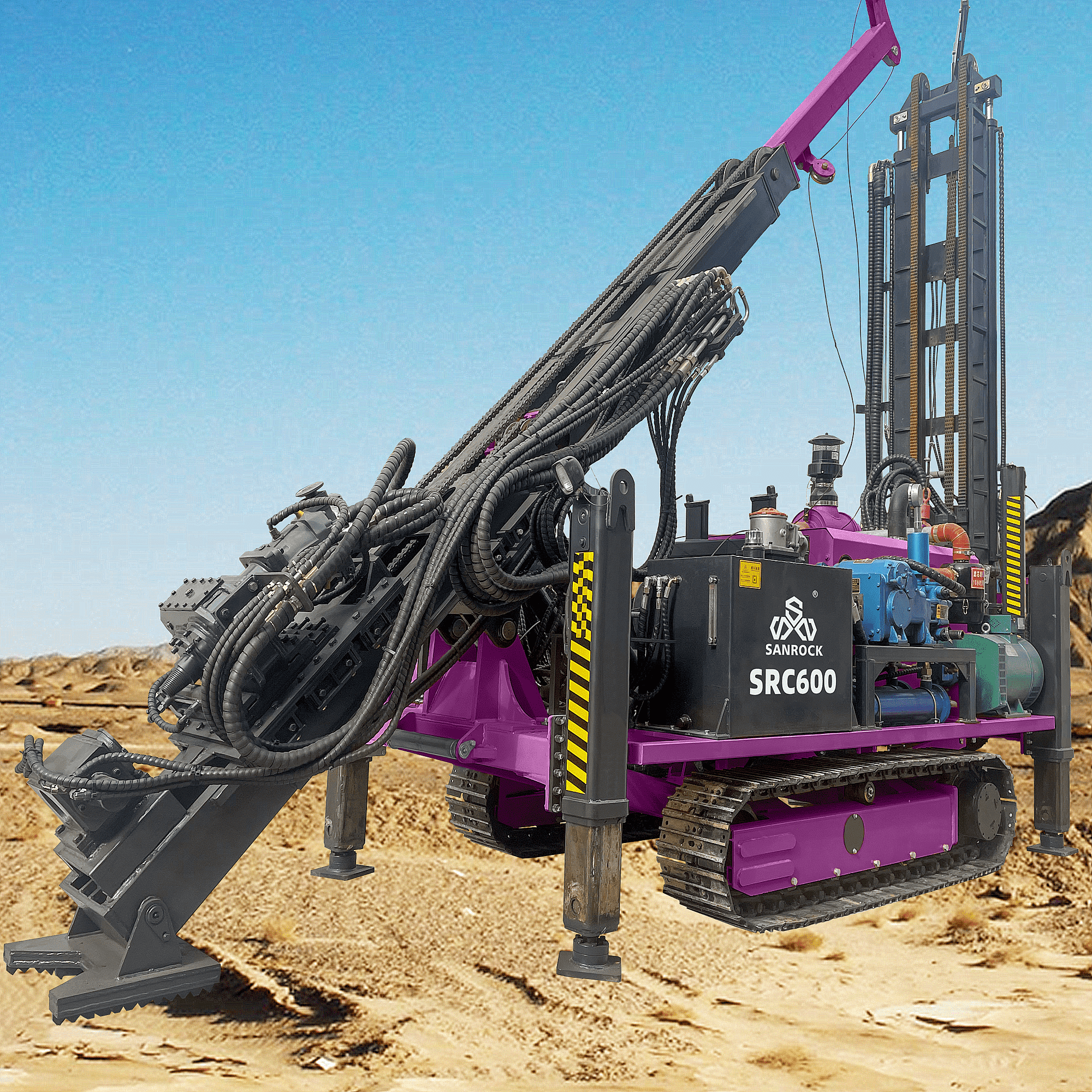

The Various Sorts Of Core Drilling Equipment and Their Applications in Various Industries

Core drilling equipment plays an important role in numerous markets, each type made for details tasks. Ruby core drilling uses accuracy for geological evaluations, while wireline systems boost performance in hard atmospheres. Auger drilling is preferred for softer dirts, and reverse flow boring is essential for deep mineral exploration. Sonic drilling attracts attention for its very little ecological effect. Comprehending these tools is necessary for choosing the best devices for any type of job. What aspects influence their efficiency?Diamond Core Boring Tools

Ruby core drilling equipment is important for numerous geological expedition and construction projects. This customized machinery uses diamond-tipped drill bits to penetrate acid rock developments, making it especially beneficial in mining, civil engineering, and environmental research studies. The efficiency of diamond core boring lies in its capacity to generate premium core examples, which are crucial for reviewing mineral deposits and understanding subsurface conditions.These rigs come in various dimensions and arrangements, from mobile units for small projects to bigger systems created for comprehensive exploration operations. The adaptability of ruby core drills allows for usage in diverse atmospheres, consisting of urban locations, remote areas, and undersea setups. Additionally, the accuracy of this equipment decreases waste and minimizes the ecological impact of exploration tasks. As markets progressively rely upon accurate geological information, ruby core boring stays a pivotal tool in progressing exploration and building approaches.

Wireline Core Exploration Equipments

Wireline core exploration systems stand for a notable improvement in piercing innovation, making it possible for efficient and specific extraction of core examples from deep geological formations. These systems use a dual-tube style, permitting the continual retrieval of core samples while reducing disruption to the geological structure. The wireline method utilizes a high-strength wire to convey the core barrel to the desired deepness, assisting in rapid healing and reducing downtime.This innovation is particularly helpful in mineral exploration, environmental examinations, and geotechnical analyses, where getting uninterrupted examples is essential for accurate analysis. The lowered handling of samples throughout access guarantees that the integrity of the core is preserved, giving important information for geological studies. Additionally, wireline systems can operate in tough problems, making them appropriate for various terrains and depths. Generally, wireline core exploration systems boost functional effectiveness and reliability, contributing significantly to the advancement of boring techniques throughout numerous markets.

Auger Exploration Equipment

Auger exploration tools act as an alternate method for subsurface exploration, matching the capabilities of wireline core boring systems. These devices utilize a helical screw to pass through the ground, properly carrying dirt and rock cuttings to the surface. Auger boring is specifically advantageous in soft to medium dirt conditions, making it perfect for geotechnical investigations, environmental evaluations, and mineral exploration.The flexibility of auger drills allows them to be made use of in numerous applications, from structure preparation to groundwater monitoring. They can be run in both upright and straight orientations, enhancing their use in constrained areas. In addition, auger drills are often favored for their cost-effectiveness and minimized sound degrees contrasted to other drilling methods. Core Drilling Equipment. Their capacity to give continuous samples makes them valuable for comprehending subsurface problems, permitting geologists and engineers to make informed choices in building and construction and resource management projects

Reverse Flow Drilling Equipment

Typically utilized in mining and environmental applications, reverse flow drilling is favored for its speed and effectiveness within deep developments. The tools is particularly beneficial in getting samples from challenging terrains or where core recuperation is much less dependable. Furthermore, its capability to provide continuous tasting makes it essential for examining natural resource. Generally, reverse blood circulation drilling devices improves the precision of subsurface examinations, making it a critical device across various markets concentrated on source removal and environmental surveillance.

Sonic Drilling Innovation

Sonic boring modern technology represents a considerable improvement in drilling methods, using high-frequency resonances to pass through numerous geological developments effectively. This strategy uses sonic powerful energy, which enables the drill bit to oscillate rapidly, allowing it to break through difficult materials internet with very little initiative. Because of this, sonic exploration is particularly effective in testing atmospheres where typical approaches might have a hard time, such as in reference dense dirts, bedrock, or saturated developments.The devices utilized in sonic boring is defined by its light-weight style and transportability, making it ideal for a selection of applications, consisting of environmental website evaluations, mineral expedition, and geotechnical investigations. Furthermore, this technique generates continuous core samples, preserving the integrity of the material for exact analysis. The lowered disturbance to surrounding soil and groundwater makes sonic piercing an environmentally pleasant choice, interesting markets focused on sustainability. Generally, sonic drilling technology improves efficiency and accuracy in core exploration procedures.

Often Asked Questions

What Precaution Are Important for Core Drilling Operations?

Crucial precaution for core boring operations consist of proper training, personal safety devices, equipment inspections, making certain steady work surface areas, keeping clear communication amongst employee, and adherence to established safety methods to reduce risks and accidents.How Do I Pick the Right Core Drilling Devices?

To pick the ideal core exploration devices, one must analyze job requirements, think about dirt and rock types, examine depth and size needs, and consider budget restrictions while guaranteeing compatibility with safety criteria and operational performance.What Is the Average Life Expectancy of Core Exploration Tools?

The typical life expectancy of core drilling tools commonly ranges from 200 to 500 hours of use, relying on factors such as material kind, exploration conditions, and devices upkeep, impacting effectiveness and general performance in various applications. Core Drilling Equipment.Can Core Boring Be Made Use Of in Ecologically Delicate Areas?

Core boring can be utilized in environmentally sensitive locations, supplied that proper procedures are taken to reduce ecological impact. Mindful preparation and adherence to policies top article aid assure that drilling tasks do not hurt breakable ecosystems.

What Maintenance Is Required for Core Drilling Equipment?

Regular maintenance of core exploration tools consists of evaluating drill little bits, oiling relocating parts, examining liquid degrees, and making certain electric systems operate effectively. Arranged servicing and punctual fixings enhance performance and prolong tools life-span sought after settings.Auger boring is favored for softer soils, and turn around blood circulation exploration is needed for deep mineral exploration. Diamond core exploration tools is crucial for various geological expedition and building tasks. Wireline core exploration systems represent a remarkable development in piercing innovation, making it possible for exact and efficient removal of core samples from deep geological developments. Auger exploration tools offer as a different approach for subsurface exploration, enhancing the abilities of wireline core drilling systems. Sonic boring technology represents a considerable advancement in boring approaches, utilizing high-frequency vibrations to permeate numerous geological formations successfully.

Report this wiki page